Product manufacturers, especially in the building products industry, are experiencing a pull from the architect and design community for environmental impact and material ingredient transparency driven by green building standards such as LEED v4 and the Living Building Challenge. This was demonstrated most recently by the Materials Pledge letter published in 2019 and signed by more than 100 international architects, designers, and partner organizations in committing to ask for materials transparency, collaboration, and preferable products that support human, climate, ecosystem, and social health.

As customer demand increases, material transparency may be the sole focus of a company’s first dive into product material health. While understanding the material and chemical make-up of products is a critical starting point, it is easy to get so focused on data collection and transparency responses that there are limited resources to dedicate to the true goal of green building standards—optimization. That is, embedding the understanding of this data into processes such as New Product Development to improve product design and ultimately lead to healthier products and materials economy. Developing an approach to transparency at scale is one way to maximize efficiency and resources to allow focusing on the things we all want to do more of—make a true sustainability impact that benefits the triple bottom line. TrueNorth, in collaboration with Toxnot and GreenCircle Certified, has worked through an innovative method for third-party verified material disclosures at scale that allows you to increase efficiency, reduce cost, and spend more time on optimization.

Why Consider a Scaled Approach?

Before diving into the process to achieve this, let’s review the benefits of transparency at scale and third-party verification. Many manufacturers get started in material transparency by creating disclosures for a small group of products. This is a great starting point, due to the need to learn and put resources towards priority requests. When beginning to create more disclosures, you’ll quickly realize how much time, resources, and cost is dedicated to one-off disclosure creation. Expanding the scope of chemical data collection to all products coming from a single manufacturing plant allows you to scale up the availability of disclosures to hundreds, potentially thousands of product variations. Additionally, data collection at scale using Toxnot increases the efficiency of data management and the bill of material (BOM) build process which enables the company to scale faster. Once data has been collected for the required breadth of products, you can respond at the time of need to specific customer requests by pulling the data necessary for that unique request. Customers value this method because their specification is not limited purely by transparency document availability. In addition, it demonstrates understanding of the product’s chemical make-up at a larger scale. By collecting data at-scale with a documented procedure, this allows the process of data collection, review, and disclosure creation to be verified, instead of each individual document . This may seem obvious, but the traditional way of building disclosures is done in a one-off manner, covering a small subset of products.

What Are the Benefits of Third-Party Verification?

At TrueNorth, we also encourage third-party verification of material transparency disclosures for your overall strategy. Some might question how verification adds value. As an expert in your products, the true value that third-party verification provides is an external perspective to shed light on potential process improvements and mistakes or errors that were made, as well as being a sounding board for disclosure decisions and deciphering the standards. With the complexity of chemicals, substances and materials, having another perspective is bound to improve your process. Moreover, when transparency documents are third-party verified, this increases customer credibility due to the advantage that an external perspective brings. Both transparency at scale and third-party verification are strategic and beneficial pieces to a mature material transparency program.

Define the Product Scope

Now that the benefits of a third-party verified material transparency program at scale are understood, let's review how to achieve this. The first step is to define your scope. To do this, identify the products or material categories to initially target for this scaled approach. It is often helpful to include marketing leadership in this decision. TrueNorth recommends looking at products with the highest demand, a smaller number of components or complex materials, and ones that have data more easily accessible and collected. For example, if products are manufactured in-house, there is likely more chemical and material data in safety data sheets (SDSs) or outside test reports than for those that are outsourced. Ensuring a strong understanding of the Bills of Materials (BOMs) for the products within scope is crucial as well. It is helpful if the products in scope are manufactured in a limited number of plants (1-3), depending on the complexity of products. Lastly, ensure that a Standard Operating Procedure (SOP) can be written for your data collection and review process, as well as your material transparency document build following the selected disclosure standard (Declare Label, Health Product Declaration etc.). Determining the initial scope for scaled transparency is an essential part of the process to ensure the project outcome meets the business and customer needs.

Select the Disclosure Method

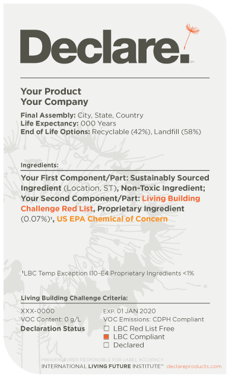

In the building products industry, there are a handful of disclosure methods and standards to choose from. Whether it’s a Declare Label, Health Product Declaration, or manufacturer inventory ensure this is chosen early on as this will affect the overall cost of the project, as well as methods of data collection. There are several factors that go into this selection including knowledge of the standard, customer pull, and the level of data collection necessary. A Declare label requires a minimum of 99% ingredient disclosure at 100ppm, unless an additional formal exception is applied . An HPD offers more wiggle room if not all data is available. You can change your selection later as the base data collected should fit all methods if collected down to 100 ppm, but this may change the overall cost.

In the building products industry, there are a handful of disclosure methods and standards to choose from. Whether it’s a Declare Label, Health Product Declaration, or manufacturer inventory ensure this is chosen early on as this will affect the overall cost of the project, as well as methods of data collection. There are several factors that go into this selection including knowledge of the standard, customer pull, and the level of data collection necessary. A Declare label requires a minimum of 99% ingredient disclosure at 100ppm, unless an additional formal exception is applied . An HPD offers more wiggle room if not all data is available. You can change your selection later as the base data collected should fit all methods if collected down to 100 ppm, but this may change the overall cost.

Gain Leadership Buy-In

Next, assemble a cost/benefit analysis to sell this vision to leadership and gain approval. This can be completed by documenting the time and cost needed to create for example: 10-20 one-off disclosures versus the ability to create hundreds of disclosures using Toxnot as your data collection tool with a closely defined scope. The up-front cost and time to collect data for a scaled approach is higher but allows for quicker document creation and customer responses over a longer period of time, as well as a lower cost per document. Be sure to include the projected cost of third-party verification at scale versus many individual verifications. Expect the quoting process to take time for the verifier to draft up as this is an innovative solution and will likely need some explanation and understanding of your process to properly quote. If you’re able to show the cost/benefit analysis of a one-off approach versus a scaled, system-based solution, the scaled solution should look favorable and assist in gaining leadership buy-in.

Data Collection & SOP Creation

Once the scope has been defined and the vision sold to leadership, it’s best to simultaneously start setting up the data collection and management process in Toxnot, as well as finalizing third-party verifier selection to partner on this vision and creating the system and material level SOP. The supplier data collection and review process will likely take a few to several months, so it’s important to include this in your overall project plan. While data collection is in progress, this is a great time to start flushing out your SOP in detail. Think of questions like “would someone with no knowledge of our process be able to understand it from this SOP?”. TrueNorth recommends running through a mock third-party verification review by using internal reviewers to ensure the robustness of the SOP. We also advise organizing it by specific sections for each material type and detailing the use of Toxnot and the overall process. You should even include a training plan for bringing new employees up to speed in preparation for future transitions and long-term maintenance.

From a cost structure perspective for verification, separate out the cost of verifying the system versus each specific material group or product category. The material group or general product category should be reviewed in detail going into specific supplier data and chemical make-up. The complexity of the materials and products within scope may change the structure of the third-party verification. In general, it is important to separate out the general process for collecting and verifying data from the review of the detailed chemical make-up for specific products. Toxnot makes organization easier by allowing categories for material sets or products by using their tagging structure or folder options. Ensure the SOP for both the material transparency system and the associated material sets in scope includes the correct links and references additional documents necessary for verification. The SOP creation is the most critical part of this process because it allows the verifier to follow your steps and verify the system and process, rather than just reviewing the data for one disclosure. Once you have completed the SOP, selected the verifier, and have finalized the initial disclosure documents, you are ready to begin verification!

System and Material Group Third-Party Verification

The third-party verification process will likely differ slightly depending on the verifier. One way to reduce costs is to perform this verification completely remotely. To do this, ensure you can share live versions of the BOM systems such as those stored in SAP or another ERP system. You can open any internal SOPs or test data that verify chemical data. Toxnot also allows the ability to add a consultant to have special viewing access to the system. This is extremely helpful and a critical piece of making the process work long-term because the verifier has access to real-time data and updates within the system. This helps them become confident when following your SOP and seeing the structure that’s been set up in Toxnot. For a system verification to succeed, it is important to demonstrate a strong knowledge of product data, the correct reporting standard, and your SOP for building up the suitable data to fit the reporting standard necessary.

The third-party verification process will likely differ slightly depending on the verifier. One way to reduce costs is to perform this verification completely remotely. To do this, ensure you can share live versions of the BOM systems such as those stored in SAP or another ERP system. You can open any internal SOPs or test data that verify chemical data. Toxnot also allows the ability to add a consultant to have special viewing access to the system. This is extremely helpful and a critical piece of making the process work long-term because the verifier has access to real-time data and updates within the system. This helps them become confident when following your SOP and seeing the structure that’s been set up in Toxnot. For a system verification to succeed, it is important to demonstrate a strong knowledge of product data, the correct reporting standard, and your SOP for building up the suitable data to fit the reporting standard necessary.

Create Disclosures on Demand

Once the system and each material group or product category is verified, get ready to create product specific disclosures based on customer demand. When there are disclosures to publish, simply email the consultant when ready for them to spot-check the data and final chemical summary/disclosure in Toxnot. Of course, doing all the up-front work of ensuring the data is collected and correct is necessary, but being able to have a verifier spot check the data knowing that you followed a verified process allows you to react more quickly to customer demand for specific products. If Declare is the selected form of disclosure and you plan to scale to 100+ labels, you may reach out to ILFI about potential strategies to streamline the verification, review, and publishing process . Since the system and process of creating disclosures has been verified, this saves the time and cost of going through a full verification for each document output.

In Summary

Let’s review the 6 steps to accomplish third-party verified material disclosures at scale:

- Define the Product Scope

- Select the Disclosure Method

- Gain Leadership Buy In

- Data Collection & SOP Creation

- System and Material Group Third-Party Verification

- Create Disclosures on Demand

While recent design community trends have demonstrated the need for increased product transparency for building products, manufacturers need more efficient solutions in order to work on product optimization. Transparency is becoming the new normal, but the goal of optimization and products that meet triple bottom line outcomes is still difficult to achieve. Developing third-party verified material transparency solutions at scale is a way for manufacturers to maximize efficiency and have time to focus on sustainability strategy, such as embedding Design for Sustainability. Results beyond transparency show employees and customers that sustainability is a serious commitment for your company. As sustainability professionals, we must be cognizant when transparency is continually taking up a large portion of time without a focus on optimization and look for affordable, scalable solutions. TrueNorth and Toxnot can help in your journey towards scaled solutions, so please contact us if interested.

. . . . .

Written by - Olivia Fritz, Co-founder, TrueNorth Collective